By Mike Anderson, P.E.

First off, know that I’ve taken some poetic license in the title – all apologies to Lerner and Loewe (and now, evidently Kurt Cobain as well). I’m hoping you forget the stretched reference by the end of the article.

Asphalt technologists have long been seeking a way to characterize the properties of asphalt binders at intermediate temperatures – at which they are expected to perform for much of their life.

In the past, tests like the ductility and penetration tests have been used at 25°C as ways to assess the stiffness and ductile behavior of the asphalt binder. Some have tried to correlate the results from these tests with durability and cracking performance.

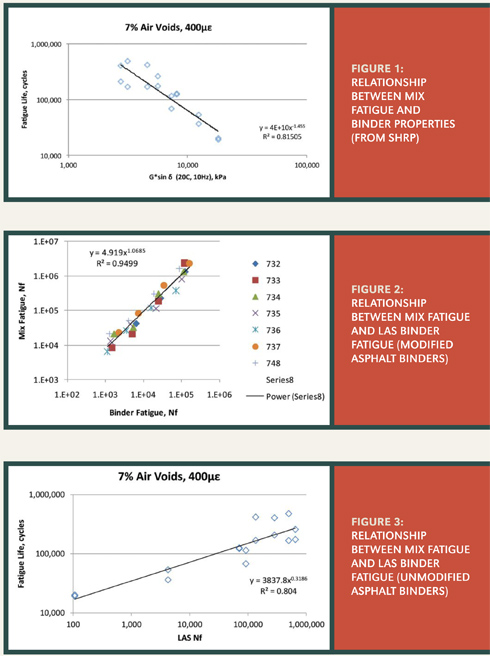

In the Strategic Highway Research Program (SHRP), researchers ultimately settled on a test to reflect the energy dissipated per load cycle using the Dynamic Shear Rheometer (DSR) – calculated as G*sin δ after long-term aging through the PAV. Mix validation work (Figure 1 below) confirmed that the cycles to failure in a mix fatigue test appeared to be related to the value of G*sin δ for the asphalt binder at the same temperature.

Twenty years have passed since the Performance-Graded (PG) Asphalt Binder specification was introduced. High and low temperature tests and parameters have been re-evaluated, modified and validated.

The intermediate parameter, despite concerns with testing reproducibility and the validity of the test and criterion, has still not been changed…perhaps because of the inherent difficulty in characterizing distress at intermediate temperatures. You might say that we’ve grown accustomed to the test.

Now, the researchers at the University of Wisconsin-Madison, led by Dr. Hussain Bahia, have developed a test for characterizing asphalt binder fatigue called the Linear Amplitude Sweep (LAS) test. In the test, an asphalt binder sample is loaded in the DSR and then tested at 10Hz using a controlled strain that is applied in a linearly-increasing manner from 0 to 30 percent over the course of 3,100 cycles (310 seconds) – so even though you could have tested all night, you won’t have to.

At the end of the test, you can use the data along with a viscoelastic continuum damage analysis to calculate the number of cycles to failure in the asphalt binder. The test looks promising to relate mixture fatigue with binder fatigue for both modified and unmodified asphalt binders (Figures 2 and 3 below).

With further testing validation, asphalt technologists may find that the Linear Amplitude Sweep test fills the bill for the long-awaited intermediate temperature binder fatigue test. And wouldn’t that be loverly?

For more information about the latest advances in asphalt binder testing, please contact Mike Anderson (manderson@asphaltinstitute.org).