With the colder weather, a young asphalt technologist’s thoughts turn from permanent deformation to cracking. Minimizing the cracking of asphalt pavements remains a major concern of user agencies. Fatigue cracking was one of the three principal distresses identified by the Strategic Highway Research Program (SHRP) that is experienced by asphalt mixtures in service. Laboratory fatigue testing of asphalt mixtures can help technologists ensure that the materials they use are not part of the problem.

With the colder weather, a young asphalt technologist’s thoughts turn from permanent deformation to cracking. Minimizing the cracking of asphalt pavements remains a major concern of user agencies. Fatigue cracking was one of the three principal distresses identified by the Strategic Highway Research Program (SHRP) that is experienced by asphalt mixtures in service. Laboratory fatigue testing of asphalt mixtures can help technologists ensure that the materials they use are not part of the problem.

Although there are many tests that have been used for fatigue cracking, probably the most commonly used in the last twenty years has been the four-point flexural beam fatigue test. It is a test conducted to evaluate the fatigue characteristics of an asphalt mixture, independent of other significant factors such as pavement structure (thickness), poor subgrade drainage and method of compaction and placement of the asphalt mix. In other words, it is a test that can help the user know that the asphalt mixture has sufficient fatigue resistance, not a test that will ensure that the asphalt mixture in service won’t exhibit fatigue cracking. Maybe a subtle difference, but the contributing factors to fatigue cracking can be varied.

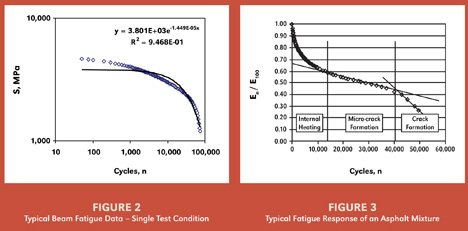

The flexural beam fatigue test is conducted by applying a repeated flexural strain (usually between 250×10-6 and 750×10-6 mm/mm) to an asphalt beam specimen in 4-point flexural loading at 10 Hz and a fixed temperature (usually 20° C) until the specimen stiffness decreases to a defined percentage of the initial stiffness. Micro-cracks in the specimen are expected to form as the stiffness of the asphalt mix specimen decreases. As the micro-cracks increase, the specimen stiffness decreases rapidly, eventually leading to crack formation and propagation. Typical data is shown in Figure 2 with stiffness plotted as a function of the number of loading cycles on a log-log scale. The reduction in stiffness is shown in Figure 3, where the ratio of stiffness to initial stiffness is plotted as a function of loading cycles.

Details about the test can be found in AASHTO T321, “Determining the Fatigue Life of Compacted Hot-Mix Asphalt (HMA) Subjected to Repeated Flexural Bending.” As currently specified in the procedure the number of cycles to failure, Nf, is defined as the loading cycle when the mixture stiffness drops to 50 percent of the original stiffness. SHRP research indicated that the cycles to failure (Nf) in the flexural beam fatigue test could be related to the actual number of loading cycles required to cause fatigue cracking of asphalt pavements.

In many cases, defining the number of cycles to failure as being the point where the stiffness is reduced to 50 percent of the original stiffness appears to coincide with the onset of crack formation. In other cases, particularly with modified asphalt binders, a lower percentage of the original stiffness may be needed. A working group within the Asphalt Mixtures Expert Task Group is continuing to evaluate this procedure with regards to data collection and analysis to provide better guidance to the users.

Unlike some of the tests for assessing permanent deformation, at this time there are no established, or widely recommended, criteria for the minimum number of cycles to failure to indicate good fatigue cracking resistance of an asphalt mixture. However, individual user agencies (California) and suppliers may have recommended criteria based on their experience with some asphalt mixtures and pavement conditions. In evaluating laboratory performance, a multiple-strain evaluation at a single temperature may provide insight into the asphalt mixture performance.

It’s enough to make you wish for summer again.

For more information or to get a quote on performing flexural beam fatigue testing and analysis, please contact either Mike Anderson (manderson@asphaltinstitute.org) or Phil Blankenship (pblankenship@asphaltinstitute.org).