If we don’t have a rutting problem, why do we have a new rutting test?

We have a new test in our lab at Asphalt Institute headquarters so of course I’m going to talk about it…

Rutting in asphalt pavement is a permanent deformation along wheel paths, appearing as grooves caused by repeated vehicle loads that compress or displace materials over time. It often stems from insufficient pavement thickness, poor compaction, or asphalt mixtures with low resistance to deformation. High temperatures can worsen the issue by softening the binder, making the pavement more prone to shear deformation.

Though rutting once posed a significant challenge, most experts agree it is no longer a widespread problem, thanks in large part to advancements from the Strategic Highway Research Program (SHRP) in the early 1990s. Innovations like performance-graded (PG) asphalt binders and Superpave mix designs have significantly improved pavement performance under heavy traffic and high temperatures, reducing severe rutting.

So, why do we need another rutting test?

As more agencies adopt balanced mix design to enhance asphalt mix durability, addressing cracking has become a key focus. A common approach involves increasing binder content or using a softer binder to improve flexibility. However, these adjustments can increase the risk of rutting if not carefully designed and tested.

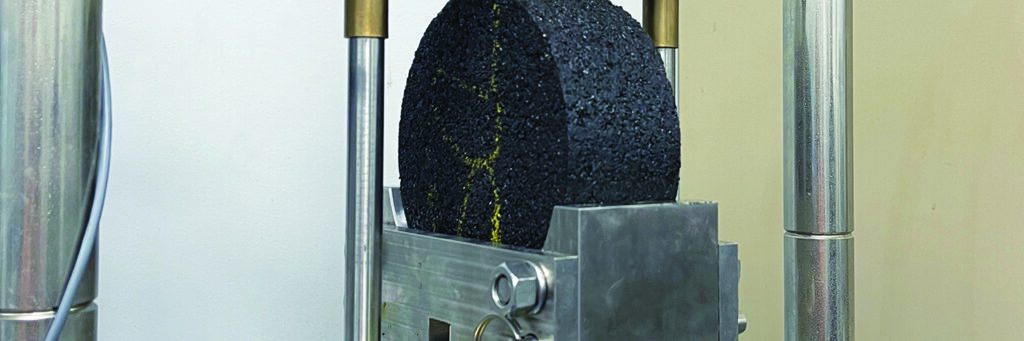

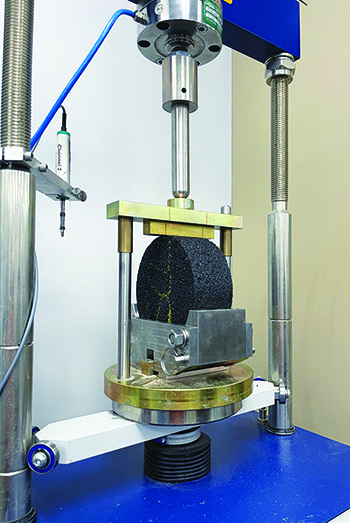

The newest test growing in popularity among materials testers and agencies in evaluating the rutting resistance of asphalt mixtures is the IDEAL-RT or Rapid Shear Rutting Test. IDEAL-RT is a performance-based test that uses indirect tensile loading to apply repeated cyclic stresses to cylindrical asphalt specimens. This approach mimics the shearing forces experienced by asphalt under vehicle loads.

The IDEAL-RT is becoming more popular than other rutting tests due to several key reasons:

1. It offers speed and efficiency, providing rapid results compared to wheel tracking tests.

2. Its ease of use makes it simple to conduct with minimal setup.

3. It is cost-effective compared to other tests.

4. It shows accurate field correlation, making it reliable for real-world performance predictions, as shown by studies by developing researchers.

5. It provides a complementary tool when used with the IDEAL-CT test to evaluate balanced performance.

IDEAL-RT is sensitive to RAP and RAS content, asphalt binder type, asphalt binder content, aggregate type, air voids and aging conditions. The coefficient of variability is below 10 percent, and many are finding it also has a good correlation with existing rutting tests, such as the Asphalt Pavement Analyzer and the Hamburg Wheel Tracking Test; and with field rutting performance.

Timeline of rutting tests for asphalt mixtures

1939: The Marshall Stability Test provided an early measure of load deformation but was not rutting-specific.

1960s: Wheel Tracking Tests, including the Hamburg Wheel Tracking Device (HWTD), became known for simulating traffic conditions and assessing rutting resistance.

1980s: The Asphalt Pavement Analyzer (APA) replicated traffic loading with a loaded wheel and rubber hose, offering reliable rutting insights.

2000s: The AMPT (Asphalt Mixture Performance Tester) was introduced, incorporating the dynamic modulus test to assess asphalt mixture stiffness and performance under various loading conditions, contributing to the understanding of rutting resistance.

2010s: The IDEAL-RT Test was introduced to offer a practical and efficient indirect tensile testing method for evaluating rutting resistance, with strong field performance correlation.

Join the Smart Asphalt community

Connect with us on Instagram to continue the discussion and ask your questions on this and other topics.