RAP • RAS • Rejuvenators

Economics • Environmental Sustainability

• Engineering Performance

What motivates the continuing increased use of recycled materials in asphalt pavements?

According to the National Asphalt Pavement Association NAPA) in 2017, it was a savings of over $2 billion and a 99 percent recycling rate of approximately 76 million tons of reclaimed asphalt pavement (RAP). Recycled asphalt shingles (RAS) are also utilized by some states with approximately one million tons recycled in 2017.

However, as the recycled materials (RAP/RAS) content increases, the stiff, brittle, aged, recycled binder often result in mixtures that may be more prone to early-life failure due to cracking. Thus, to ensure adequate performance, agencies typically limit the RAP content to 15-20 percent and the RAS content to 3-5 percent, both by weight of the mixture and sometimes allow softer virgin base asphalt binders.

Recent efforts have sought to double the recycled materials content in asphalt mixtures through the use of mitigation strategies that include utilizing a softer virgin base asphalt binder and/or adding a rejuvenator to partially restore the rheology of the binder blend (recycled binder and virgin base asphalt binder) in an effort to provide adequate mixture cracking performance. With those efforts comes the recognition that every combination of virgin base asphalt binder, virgin aggregate, RAP, RAS and rejuvenator (and other additives) is unique and must be engineered to provide adequate performance.

A standard method for selecting an appropriate rejuvenator dose is needed, as are recommended guidelines for component materials selection and evaluation tools for binder blends and mixtures that consider aging and laboratory performance thresholds needed for successful materials combinations.

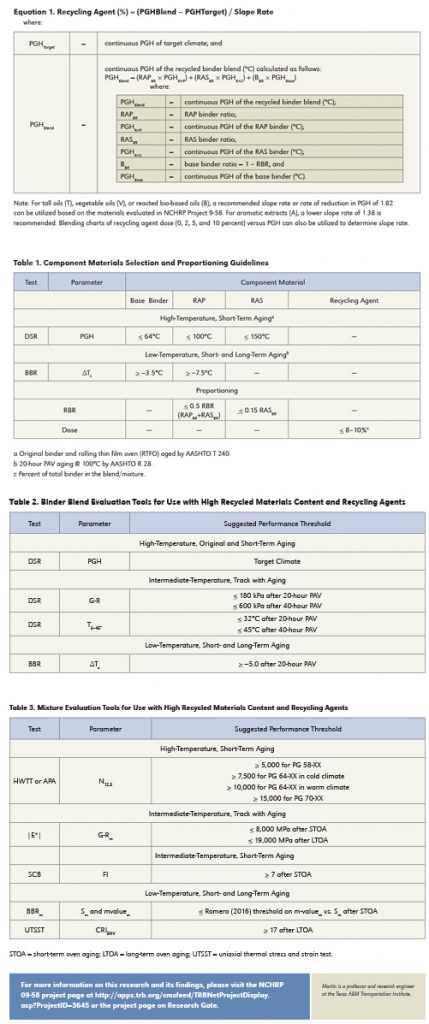

A recently completed research project sponsored by the National Cooperative Highway Research Program (NCHRP) – identified as NCHRP 09-58 – developed a draft AASHTO standard practice that includes these methods, guidelines and tools as shown in Equation 1 and Tables 1-3.

The draft AASHTO standard practice is a starting point and implementation through field demonstration projects is recommended as the next step. Other aspects of performance also need to be evaluated for asphalt mixtures with high recycled materials contents, such as durability in terms of moisture susceptibility. Interactions and compatibility with other additives such as warm mix compaction aids and antioxidants also need to be explored – further highlighting the need for performance-based evaluation tools. Finally, the availability of the recycled binder and subsequent blending with the virgin base asphalt binder is still unknown and will continue to be a subject of interest to asphalt researchers and practitioners alike.

Martin is a professor and research engineer at the Texas A&M Transportation Institute.

Click here for a full display version of this article.