A closer look at the ‘P-401 Plant Mix Bituminous Pavements’ section of ‘Advisory Circular (AC) 150/5370-10H, Standard Specifications for Construction of Airports’

Charles Kettering, inventor and founder of Delco, once said, “People are very open-minded about new things, as long as they’re exactly like the old ones.”

The Federal Aviation Administration (FAA) recently released the latest revision of their P-401 construction specification and it contains some changes that are markedly different and improved from the old ones. Although there were many changes, this article will outline six of the most important ones for asphalt contractors, consultants, suppliers and testing labs.

1.

Increased contractor quality control

The FAA intentionally focused on the idea of contractor quality control (QC) to a greater degree than ever before, not only in P-401, but throughout their Advisory Circular (AC) 150/5370-10H, “Standard Specifications for Construction of Airports.”

The demands on asphalt airfield pavements and the requirements for their safety and longevity necessitate a focus on quality. Lana Logan, Regional Engineer for the FAA’s Southwest Airports Division says, “The FAA is so passionate about quality control that we have now included a separate pay item for it.”

FAA has made a point to say that QC is more than just test results. It also includes using proper materials, workmanship, equipment, inspection, documentation and communication. New verbiage has been inserted throughout the specification addressing these key areas. The QC pay item is “encouraged” for all projects and is “required” if the project includes over $500,000 worth of paving.

2.

More opportunity for highway asphalt mixtures

The FAA has increased the opportunities for highway asphalt mixtures to be used in airfield construction. Previously, there was language in the specification that said the stricter P-401 guidelines had to be used if the pavement was subject to aircraft loadings of greater than 12,500 pounds. The new cutoff is 30,000 pounds, which allows considerably more leeway to use less stringent state highway specifications.

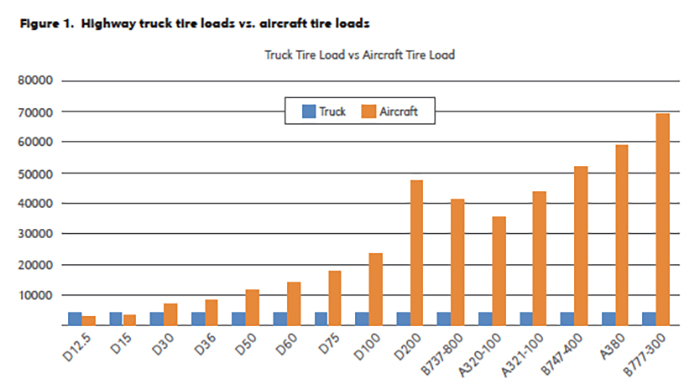

It’s important to understand why airfields often need a stronger asphalt mixture than highways. Aircraft loads can exceed one million pounds, whereas it would be extremely rare for even a very large truck to exceed one hundred thousand pounds gross weight. Additionally, aircraft tire pressures can exceed 300 psi, versus semi-truck tire pressures that average around 100 psi.

The reasoning behind the FAA change is that typical truck tire loads are similar to aircraft tire loads up to about 30,000-pound aircraft loads. Doug Johnson of the FAA created Figure 1, which clearly demonstrates the differences between typical highway truck loading and different aircraft loads.

It’s clear from the figure that loading from aircraft larger than 30,000 pounds is significantly higher than typical truck tire loads and requires a stronger asphalt mixture to withstand the stresses generated by the larger aircraft.

3.

Adjustment to gradation bands

The aggregate gradation bands have been adjusted since the last version of P-401. Aggregate gradations in mixtures from last year may not meet the new gradation limits. It should be noted that the gradation bands are still called Gradation 1, Gradation 2 and Gradation 3. The adjustments modify the former FAA limits to match Table 5 of the Department of Defense Unified Facilities Guide Specifications (UFGS) Section 32 12 15.13 asphalt mixture gradations.

For those more familiar with Superpave asphalt mix gradations, FAA Gradation 1 is analogous to a 19.0mm nominal maximum aggregate size (NMAS) mix. FAA Gradation 2 is analogous to a 12.5mm NMAS mix, and Gradation 3 is analogous to a 9.5mm NMAS mix.

4.

New guidance on grade selection

The FAA has provided additional guidance regarding the selection of asphalt binder grades in the new P-401. This new guidance takes into account that the binder in asphalt mixtures inherently responds differently depending on the amount of time it is loaded.

Asphalt Institute’s “MS-25 – Asphalt Binder Testing Manual” says, “Asphalt binders tend to behave more like viscous materials at high temperature and when the load is applied for a long period of time. When the loading time is short, or the temperature very low, asphalt binders tend to behave like elastic materials.”

With this concept in mind, the FAA has added a column to their table in section 401-2.3 showing the required grade bump in addition to the project area’s environmental grade. Instead of selecting the high-temperature grade bump based solely on the aircraft gross weight, designers will now also need to use different selection criteria if the pavement area has slow or stationary aircraft. Note that the low-temperature grade remains the same as the environmental base grade – only the high-temperature grade is changed.

5.

New mechanical test

The FAA now requires a new mechanical test for asphalt mixtures using the P-401 specification – the Asphalt Pavement Analyzer (APA). As shown in Figure 3, the APA is a Loaded Wheel Tester (LWT) used mainly for evaluating permanent deformation, which we call rutting. In its basic function (there are other options), concave wheels pneumatically load pressurized hoses on top of compacted asphalt specimens for a given number of passes at a chosen temperature. Rectangular slab or beam specimens or cylindrical specimens can be tested at the same time using gyratory, Marshall or vibratory beam samples.

The test method used for the APA is AASHTO T 340. APA testing variables include the test temperature, magnitude of the load applied, the hose pressure and the number of cycles. For highways, AASHTO T 340 says to run the test at the specifying agency’s standard high-temperature grade (environmental grade). The hose pressure is set to 100 psi, the load is set to 100 lbs., and the test is run for 8,000 cycles. The pass/fail criterion is typically a maximum rut depth, often around 10mm, or even less for mixes using polymerized binders.

The FAA spec requires a test temperature of 64°C at a hose pressure of 250 psi for 4,000 cycles. The manufacturer of the APA, Pavement Technology Inc (PTI) has developed high-pressure hoses capable of meeting the 250-psi criterion. However, the FAA is allowing two other options if the testing laboratory is currently incapable of performing the test with the hose pressure criterion. The first is to use the standard 100 psi hose pressure, but the pass/fail criterion moves to a maximum of 5mm rutting after 8,000 passes. The second requires FAA approval but allows the Hamburg wheel test to be used with a pass/fail criterion of less than 10mm rutting after 20,000 passes.

6.

Density calculation

The new P-401 adapts the way pavement density is calculated to be in line with the method contractors, consultants and laboratories use most often. Before this latest revision, pavement density was expressed at a percentage of the average lab-molded bulk specific gravity (Gmb) of the asphalt mixture. It is now expressed as a percentage of the theoretical maximum density (TMD).

The term “density” is only properly understood by the context in which it is used. The term “density” is actually defined as the mass per unit volume, or unit weight. The units, for example, might be expressed in pounds per cubic foot (pcf) or in grams per cubic centimeter (g/cc). Additionally, previous FAA specifications determined density in terms of specific gravity. One has to multiply the specific gravity by the unit weight of water (usually 62.4 pcf or 1.0 g/cc) to get the material density.

What many people in the industry actually mean when they use the term “density” would be more correctly defined as “percent relative density.” That means that the density of the pavement is expressed as a percentage of the density of something else. Percent relative density has no units since the pavement density is divided by another density, mathematically canceling out the units.

For example, a pavement density might be 147.5 pounds per cubic foot. The unit volume would include the aggregate, the binder and the air voids in the mix. The TMD would be the density if we could squeeze out all the air voids and just leave the volume of the aggregate and binder, without any air voids. Since the volume is smaller without air, the TMD would be a larger number, for example, 156.1 pounds per cubic foot (pcf). The percent relative density, in this case, would be 100 x (147.5/156.1) = 94.5 percent.

It’s important to note the difference between the way percent relative density is calculated in the new P-401, because the magnitude of the number will be different. Using the same example, let’s suppose that the average lab-molded specific gravity was 2.402. The lab-molded density would be 2.402 x 62.4 pcf = 149.9 pcf. Using the old specification, the reported density would be 100 x (149.9/156.1) = 96.0 percent, which is 1.5 percent higher than how the percent relative density is calculated in the new specification for this example. The actual density didn’t change. It’s just that now it’s expressed as a percentage of TMD instead of the lab-molded specific gravity.

Summary

In summary, because materials, construction methods and test methods are always changing, specifications also need to periodically change to keep up. FAA’s newest revision (10H) of AC 150/5370, “Standard Specifications for Construction of Airports,” which includes Item P-401, “Asphalt Mix Pavement,” was released on December 21, 2018.

The FAA made a lot of minor changes in the new spec, but also some substantial ones. They all work together to improve the ability of contractors, consultants, suppliers and testing labs to understand exactly what the FAA wants for its asphalt pavements. That better understanding also increases the likelihood that the FAA will receive the asphalt pavement quality they desire to meet their needs.

Gierhart is an Asphalt Institute Senior Regional Engineer based in Oklahoma.

Read the print magazine version of this article with all the images.