Many agencies are turning to life-cycle cost analysis (LCCA) as a means of evaluating the long-term economic viability of pavement designs. As such, it is important for each agency to conduct a realistic assessment of pavement economics in order to provide objective input into the life-cycle cost analysis.

Many agencies are turning to life-cycle cost analysis (LCCA) as a means of evaluating the long-term economic viability of pavement designs. As such, it is important for each agency to conduct a realistic assessment of pavement economics in order to provide objective input into the life-cycle cost analysis.

The determination of life-cycle costs of alternative pavement types is an important part of a rational means for decision making. The Federal Highway Administration (FHWA) in Demonstration Project No. 115 (FHWA, 1998) articulates an appropriate and non-biased method for life-cycle cost analysis. It uses the net present value (NPV) approach of determining the costs of several alternatives.

The Asphalt Pavement Alliance has developed software capable of performing life-cycle cost analysis using the FHWA procedure. This software can be downloaded for free from www.asphaltroads.org.

Net present value method

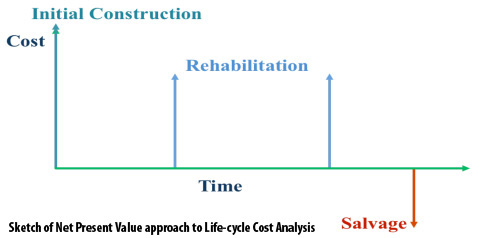

A simplified sketch of how the net present value method of life cycle cost analysis works is shown in the graphic. The initial cost, the rehabilitation costs and the salvage value are all considered according to what their values would be in terms of the present value of money. Then a discount rate factor is applied to account for the time value of money, and the future rehabilitation costs and salvage value are discounted back to the present. This simply means that dollars in the present are presumed to be worth more than dollars in the future. The life-cycle cost is then the sum of the initial costs and discounted future costs and salvage value.

In determining the life-cycle cost of a pavement, it is important to include only those costs which pertain to the pavement. In other words, common costs such as striping, sod, guardrails, etc. should not be included unless the difference in pavement type causes a cost differential in these items.

Initial cost

The basis for cost of the initial construction should be unit prices from bid records of projects constructed over the last two or three years, and only representative prices should be included. For example, very small projects or projects where paving is only a minor component of the total cost may cause unit prices to be skewed.

It is realistic to consider the initial cost both by itself and as part of the life-cycle cost analysis. This recognizes that the agency is constrained by an annual budget, and needs to examine the short-term ramifications of expenditures as well as the long-term impact of pavement type decisions.

Predicted performance life

It is important that the agency refer to its past experiences with different pavement types. It is recommended that at least two categories of asphalt pavements be used: pavement less than eight inches thick over granular base and pavement greater than eight inches. It is important to document the performance from the time of original construction or reconstruction until the next reconstruction. In other words, a simple overlay or mill and fill are rehabilitation activities and do not constitute the end of the pavement life.

The analysis period should be long enough to capture major rehabilitation or reconstruction activities for all pavement options. When the Perpetual Pavement concept is used, reconstruction occurs well outside the normal analysis period of 30 to 50 years. The Asphalt Pavement Alliance recommends that the analysis period be no less than 40 years and that it include at least one rehabilitation activity for each pavement option. This complies with the FHWA-recommended minimum of 35 years.

It is very important that the predicted timing and extent of the first rehabilitation be based upon actual construction and pavement management data rather than memory or judgment. Information collected from all 50 state highway agencies shows that the most frequently occurring performance period used between initial construction and first overlay is 20 years, while the average for this same interval was 15.7 years. The same information from 50 states showed the average performance period used between first and second overlay was another 12.0 years, so the average time from initial construction to second overlay is 27.7 years. These figures correspond well with an FHWA study of asphalt overlay performance from the Long-Term Pavement Performance study which showed that most overlays lasted for over 15 years and many lasted for more than 20 years before significant distress was noted.

The above data and policies reflect averages, and, in some cases, engineering judgment, rather than data collected over a number of decades and rehabilitation practices in different jurisdictions. They do not account for recent improvements in the selection of materials, mix design procedures and pavement design methods. The implementation of Superpave occurred in the mid-1990s, and SMA was adopted by a number of agencies throughout the 1990s, so the impacts of these improvements on performance have not been fully realized. Such improvements come at higher costs for materials, so it is logical to give some conservative credit for performance although it may not be completely documented. One approach, suggested by Von Quintus, is to use a technique known as ?survival analysis? to extrapolate the performance of newer technologies.

Maintenance costs

Maintenance costs are frequently difficult to define because of either a lack of record keeping or accounting that does not appropriately discriminate between different types of maintenance activities. Maintenance costs in a life-cycle cost analysis usually have minimal impact when compared to the initial and first rehabilitation costs. If maintenance costs are used within an LCCA procedure, then historical documentation of actual pavement activities and expenditures should be used. As with rehabilitation, unrealistically frequent or inappropriate maintenance activities can artificially increase life-cycle cost.

Salvage value

Because some or all of the pavement structure continues to serve its purposes beyond the analysis period, it is important to account for its condition at the end of the analysis period. Salvage value is typically the term used in life-cycle cost analysis, but FHWA chooses to use the term “remaining service life” (RSL) value to distinguish the idea that the pavement will continue to serve beyond the end of the analysis period. Another method used is to consider the salvage value as some percentage of the initial pavement construction cost.

Discount rate

The selection of a discount rate in life-cycle costing can be contentious because there is a great deal of uncertainty associated with future interest rates and inflation. An unreasonably low or negative discount rate essentially means that it would not matter financially if a project were to be constructed today or 10 years from now. This would overemphasize the influence of uncertain future costs. Too high a discount rate would overemphasize the importance of the initial cost.

The Mechanistic-Empirical Design Guide (MEPDG) from the American Association of State Highway and Transportation Officials recommends establishing the discount rate according to that set by the federal Office of Management and Budget Circular A-94, which is updated annually.

Based upon a survey of states an average discount rate of 3.7 percent is used in the U.S. with a range between 2.3 and 6.0 percent. It is interesting to note that 23 states have chosen to use a discount rate of 4 percent when performing life-cycle cost analysis.

Summary

Life-cycle cost analysis is a tool that can help evaluate the long-term benefit of structures. However, it must be correctly used and the data used in conducting LCCA must be derived from