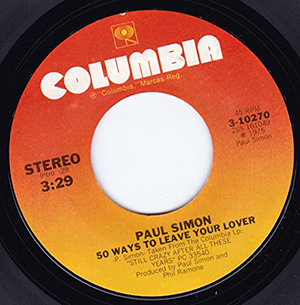

The answer is all inside our lab”, Wes said to me

“The process is easy if you take it logically

We like to help folks understand its properties

There must be fifty ways to test your asphalt”

He said, “It really doesn’t take a lot of time

And I hope your understanding won’t

get lost in this sad rhyme

But I repeat myself, our technology’s sublime

There must be fifty ways to test your asphalt

Fifty ways to test your asphalt”

Rotational Vis, Chris

Watch for the flash, Cash

Solubility, Brie

Just listen to me

Run DSR, Lars

Phase angle and G-Star

Start the PAV, Lee and get your PG

That’s all I’ve got… please don’t tell Paul Simon.

I realized that this was the fiftieth “Lab Corner” article that I have written, so I was trying to come up with a good way of commemorating that milestone. Evidently butchering a former number one single from the seventies was the best idea I had.

Being an engineer, I’ve always liked numbers and lists, so I thought for this numerically-significant edition, I would share some of my favorite numbers in the world of asphalt and elsewhere.

101 The number of years the Asphalt Institute (AI) has been in existence

28.83 The number of years AI has let me play in the asphalt lab

73 The best number according to Dr. Sheldon Cooper

2.1 The air pressure (MPa) used in the Pressure Aging Vessel procedure

4 The average number of times in a normal year that I will spill asphalt binder on the counter or floor in a sufficient quantity

24 The average number of eyeballs rolled at me by technicians in a normal year when I spill asphalt binder on the counter or floor in a sufficient quantity

163 The temperature (degrees C) used for short-term oven conditioning – whether in the Rolling Thin Film Oven (RTFO) or Thin Film Oven (TFO) procedures. Intended to simulate mixing temperature of hot-mix asphalt at an asphalt mixture facility

135 The temperature (degrees C) used for kinematic viscosity and rotational viscosity. Intended to simulate the temperature of the asphalt binder at laydown/compaction

230 The minimum temperature (degrees C) for the flashpoint of paving grade asphalt binders using the Cleveland Open Cup Flash Point test procedure

23 The number of my favorite NBA player (Someone once asked me why he was my favorite…so I took it personally.)

315 The number of the AASHTO test procedure for the Dynamic Shear Rheometer (DSR). I’m also partial to its ASTM equivalent – 7175

12, 10, 1 The target applied shear strain levels (%) for O-DSR, R-DSR, and P-DSR (otherwise known as Original, RTFO-aged, and PAV-aged asphalt binder)

312 The number of the AASHTO test procedure for the Superpave Gyratory Compactor. I’m also partial to its ASTM equivalent – 6925

1.00 What the angle of gyration (in degrees) was supposed to be in the SHRP experiments establishing the operating parameters of the Superpave gyratory compactor

1.27 What the angle of gyration (in degrees) really was in the SHRP experiments establishing the operating parameters of the Superpave gyratory compactor because a cam was not machined correctly in Lexington, KY

1.25 What the final external angle of gyration (in degrees) is for the Superpave gyratory compactor procedure because 1.27 degrees was just too weird

1.16 What the internal angle of gyration (in degrees) is for the Superpave gyratory compactor because what matters is what the mix sees during compaction

1984 Might as well jump

99.0 The minimum requirement for solubility (%) of paving grade asphalt binders – only 0.44% away from equaling Ivory soap

12-15 The typical range of minimum Voids in the Mineral Aggregate (VMA) required for 25 mm NMAS to 9.5-mm NMAS asphalt mixtures (%)

112, 22.5 Number of blows per side applied to a 6-inch diameter Marshall specimen to simulate 75 blows per side applied to a 4-inch diameter Marshall specimen; Mass (lbs.) of the sliding weight used for the 6-inch diameter Marshall

128 Ounces of Gatorade consumed after compacting twelve 6-inch diameter Marshall specimens by hand for a large stone asphalt mixture in Eastern Kentucky in 1989

Last (repeated) number…1. As in one grateful author for the opportunity to share some thoughts with you through fifty Lab Corner editions.

Mike Anderson is the Director of Research and Laboratory Services at the Asphalt Institute.