The benefits of using modified asphalt binders are widely recognized—primarily, improved rutting resistance, reduced fatigue cracking and less cold-temperature cracking.

These improvements in performance, durability and reduced life cycle costs, compared to unmodified asphalts, have led to widespread use of modified asphalts.

Because of this increasing use of modified asphalts, there is considerable interest in evaluating various non-traditional or alternative materials as potential modifiers. As an example, in the summer issue of this magazine, there was an article on using printer/copier toner as an asphalt additive. The reasons for evaluating new materials include improving performance, reducing waste disposal costs and reducing the cost of the modifier additives.

Now, we’ll take a look at using nanoclays as an asphalt modifier.

What are nanoclays?

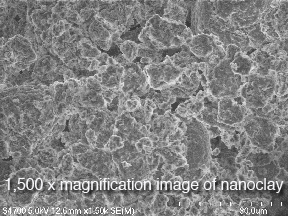

Nanoclays are tiny particles of layered mineral silicates. How tiny? A nanometer is one billionth of a meter and 10 nanometers are only one ten thousandth the diameter of a human hair.

Clays can be organized into several classes, including montmorillonite, bentonite, kaolinite, and a few others. It should be noted that not all clays being looked at as asphalt modifiers are nano-sized. Some may have only one dimension that is nano-sized, e.g., the thickness of bentonite or montmorillonite platelets.

Nanoclays are known to enhance the properties of many polymers. Nanoclays are used to improve modulus and tensile strength, flame resistance and thermal and structural properties of many materials.

Montmorillonite is the most common type of nanoclay used in materials applications. Montmorillonite has several qualities that make it an excellent base for manipulation through nanotechnology.

Michigan Tech research

A team at Michigan Technical University led by Professor Zhanping You has been evaluating the use of nanoclays to modify asphalt. You’s team worked with several types of nanoclay. According to Dr. You, two to four percent of the nanoclay (by weight of the asphalt) in dry-particle form was slowly added into the control asphalt binder. The mixing was done at 275°F (135°C) using a high-shear mixer rotating at 6000 rpms to produce the modified binders. The mixing process lasted about two hours.

The resulting modified binders were tested using Superpave equipment and procedures. The DSR viscosity, dynamic shear modulus (G*), and direct tension values were determined. The test results indicated that the modified binders were significantly more viscous or stiffer, indicating improved rutting resistance.

Dr. You describes his team’s work, as follows, “Nano-modified asphalt is in its early stage of research. This small research could bring big impact on the asphalt industry. As we know, nanoclay is widely used in the modification of polymer. It could improve the mechanical properties, heat resistance and biodegradability of hybrid materials.

“The raw nanoclay is montmorillonite, a 2 to 1 layered smectite clay mineral with a plate structure. The major sodium ions constitute the layer, and this structure has high expansion pressure. It readily leads to exfoliation and dispersion of crystals in the form of micro-particles or layers.

“The microstructure of nanoclay may be useful for binder modification. The high-temperature performance of nanoclay modified asphalt binder and mixture was significantly improved. However, the low-temperature and fatigue cracking performance of nanoclay modified asphalt binder and mixture shall be further studied.”

Dr. You cautions that the low-temperature and fatigue cracking properties of nanoclay modified binders and mixtures may not be improved. Nanoclay could have a negative effect on the low temperature and thermal cracking performance of asphalt mixtures. Additional testing to determine low temperature performance is needed

You’s lab is also testing how other nanomaterials, including nano-silica and nanocomposites, will affect asphalt durability.

Nanoclay and emulsions

In a presentation at an Asphalt Emulsion Manufacturers’ Association (AEMA) meeting in 2010, Dr. Alan James, Senior Scientist with AkzoNobel Asphalt Applications, discussed the use of clay-stabilized emulsions. While clay has been traditionally used as an emulsifier, in this application it is being used to modify the asphalt residue properties.

James said that clay-stabilized emulsions are a way to make nano composites using a relatively cool process. The approach is to disperse clay (without surface modification) in water. Then hot asphalt is mixed in, forming the emulsion in which each small (10-12 micron) asphalt particle is surrounded by even smaller clay particles.

The process takes place at less than 212ºF (100ºC), and the emulsions are stable and easy to handle. When the emulsion dries, the residue comprises a mixture of clay and asphalt with significantly altered properties. To provide additional performance improvements, polymer-modified asphalts can be emulsified or latex can be added to the clay-stabilized emulsion.

Dr. Peter Zhou, Senior Research Chemist with AkzoNobel’s Specialty Chemicals, has done further work with the clay/asphalt emulsions. Zhou recovers the residues by evaporation at low temperature and then characterizes them before and after accelerated aging. A series of Performance Graded (PG) rheological tests are then used to predict the service life at high and low temperatures. Traditional tests, such as penetration and softening point, have also been performed.

According to Zhou, the clay-modified binders have drastically altered rheological properties, with higher high temperature viscosities but relatively unchanged low-temperature properties. From these properties Zhou concludes, “In principle, these binder properties should allow the design of stiffer pavements with less tendency to rut in hot weather or to find a use in trackless surface seals.”

Conclusion

Nanoclays appear to have beneficial impact on the high-temperature properties of asphalt binders modified with these materials. Additional research and evaluation is needed to determine whether nanoclay modified binders improve low temperature and fatigue performance. When this information is available, a new type of asphalt modifier may become more widely used.

Dwight Walker is a contributing editor for Asphalt magazine and is a consulting engineer specializing in asphalt materials, construction and preservation.