As warm mix asphalt (WMA) technologies have increased in usage they have had many positive impacts, but also raised many questions.

User agencies want to increase their knowledge of how WMA affects both immediate and long-term performance. Will the asphalt absorb differently? Will fatigue life be increased since the aging effect is less? Will the pavement crack more or less?

With the economic benefit (fuel savings) of lowering plant production temperatures, WMA is here to stay. So, what do we need to do to better understand the effects of using WMA?

One important area that affects the pavement performance is mixture aging. When using WMA, we typically lower the production temperature at the plant. The mix should then see less short-term aging in the field. If that is the case, it puts into question whether the many laboratory assumptions on absorption and aging for HMA are still accurate for WMA?

How long should we oven-age WMA to simulate the absorption and stiffness that occurs in the plant during production? Current practice is to age the loose mix in the oven at the lower recommended temperature by the WMA manufacturer versus the standard construction temperature of HMA, such as 275°F.

Contrary to that, others have increased the loose mix aging time to pass rutting tests. This longer aging time corresponds with a “stiffening of the mix” which results in an improved resistance to rutting but can lower the ability of the mix to resist fatigue related cracking.

All this confusion is a result of our industry not knowing how to handle WMA in the laboratory. The Asphalt Institute worked with the Kentucky Transportation Cabinet and Federal Highway Administration to take a deeper look at what takes place during the aging process. This laboratory study was accomplished by varying oven aging times and then testing using a variety of performance-related testing. This article focuses on Flow Number (FN) testing for evaluation of rutting potential and Disk-Shaped Compact Tension testing (DC(t)) to evaluate fatigue cracking.

Design of the mix and experiment

A typical Kentucky 9.5mm nominal maximum aggregate size mixture was selected along with a local Performance Grade 64-22 binder. The job mix formula selected was a Superpave, Kentucky Class 2 asphalt surface which is typically placed on non-primary routes with up to 3 million ESALS. The warm mix technology selected was a chemical additive which is added to the binder prior to mixing with the aggregate.

In order to evaluate the effects of both temperature and aging time, two temperatures and four aging periods were selected. The temperatures selected for loose mix aging were 135°C (275°F) and 114°C (240°F) for the HMA and WMA mixes respectively. The four aging times selected were 0.5, 2, 4 and 8 hours.

Sample preparation

Eight sets of samples were prepared for testing, four sets representing the aging periods for each mixing temperature. The aggregates and asphalt were mixed and aged according to “AASHTO R-30, Mixture Conditioning of Hot-Mix Asphalt,” but disregarded standard aging periods for the purpose of this experiment. Four replicate samples were used for Flow Number testing and three for DC(t) testing.

Flow Number testing

Flow Number is a new way to test the rutting potential. The higher the Flow Number, the more resistant to rutting a pavement should be. Flow Number was measured using the Asphalt Mixture Performance Tester (AMPT). For this study, a deviator stress of 600kPa (87Psi) and a five percent initial contact stress of 30kPa (4.4Psi) were used with no confining stress. These test conditions were selected because they are the same of those used in the NCHRP 9-29 inter-laboratory study which evaluated the AMPT.

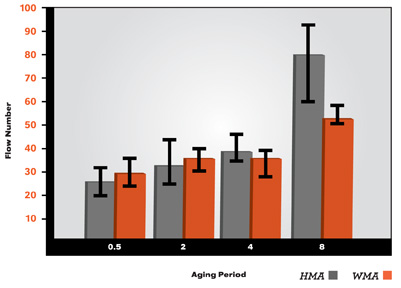

All samples were run to five percent total strain. A test temperature of 55¿C (131°F) was selected using LTPPBind 98 percent reliable pavement temperature at 20mm (.79in) depth. These test conditions simulate hot, summer traffic in a KY climate. FN data is summarized in Figure 1. As would be expected the flow number increases with increased aging in both the WMA and HMA mixes. The WMA mix performed slightly better at the lower aging periods (0.5 and 2hr) while the HMA mixes performed better at the longer aging periods (4 and 8hr). Despite this, statistical analysis did not show the reduction in loose mix aging temperature to be a significant factor in flow number testing results.

Disk Shaped Compact Tension testing

The DC(t) test allows us to determine the potential cracking properties of a mix by measuring its fracture energy. The higher the fracture energy the less likely the pavement is to have its service life reduced by cracking. The testing temperatures were selected as -2 (28), -12 (10) and -22¿C (-7¿F) in accordance with ASTM D 7313-07a as standardized by the University of Illinois. Tests were performed with a constant crack mouth opening displacement of 1mm/min (0.00066in/s). The test was run until the load necessary to maintain this rate is reduced to 0.1Kn (22.5lbf). At the -2°C (28°F) testing temperature the results were as expected, with the WMA being less brittle, and performing significantly better than the HMA mixes in terms of fracture energy. The HMA mixes had a higher peak load and tended to fail more aggressively. There was also a trend of decreasing fracture energy with increased aging period.

As the mixes enter the quasi-brittle state in -12°C (10°F) and -22°C (-7°F) testing, there is no significant difference in fracture energy or peak load between the HMA and WMA mixes. There is also no significant difference between the different aging periods at these temperatures, the lower the testing temperatures the less significant aging period becomes. The data suggest that the chemical additive allows for the lowering of the mixing and compaction temperatures by 31°C (35°F) with no significant effect on the low temperature performance.

The test data suggest that there is not a significant difference in the performance of the warm and hot mixes at the various aging times and temperatures for DC(t) and FN testing. This indicates that it would be unnecessary to take any steps to equilibrate the properties of the warm and hot mixes; this includes increasing the loose mix aging time of warm asphalts. Based on this data, warm and hot mixes can be treated the same with regard to aging time.

(FIGURE 1 Flow Number (FN) using the HMA and WMA mixes as a function of aging period. Each data point represents the average of 4 test, error bars represent one standard deviation.)

(FIGURE 1 Flow Number (FN) using the HMA and WMA mixes as a function of aging period. Each data point represents the average of 4 test, error bars represent one standard deviation.)

Thomas is a recent graduate of the University of Kentucky, School of Engineering and a former Asphalt Institute intern. Thomas now works for the Kentucky Transportation Cabinet in Frankfort, KY.