One of my favorite movies is “Apollo 13.” I know it’s a movie and not a documentary, but it is still amazing to me to think about how the Apollo 13 crew and NASA engineers at mission control worked the problem facing the astronauts.

In one tense part of the movie, NASA Flight Director Gene Kranz (played by Ed Harris) was quoted with the iconic tagline “failure is not an option” in describing the efforts NASA needed to bring the crew home safely. That may not actually have been said at the time, rarely are we walking around with classic sound bites ready to employ in the perfect situation, but it made for a great scene nonetheless and did keep true to the general mindset of the NASA engineers. Gene Kranz even chose it as the title of his memoir.

In the current version of the Performance Graded (PG) Asphalt Binder Specification, as provided in AASHTO M 320 (ASTM D6373), the parameters related to performance – rutting and cracking (fatigue and thermal) – are based on small stress-small strain measurements intended to test the asphalt binder in a state where a linear response is expected and significant damage to the specimen is not expected to occur. Meaning that for the PG specification in its current form, testing an asphalt binder to determine failure is not an option. What do we mean by “failure” tests? It means that we are testing a sample in a way such that the specimen is damaged and cannot be tested again once the test is complete without creating a new sample. Failure tests can be very useful as they provide information on the ultimate strength of a material, but they have some drawbacks as well.

One major drawback is that they typically have higher variability than tests that are conducted in the linear viscoelastic region. Damage is a non-linear response and is affected by more than just the inherent properties of the material being tested. Specimen imperfections during preparation can lead to stress concentrations which can lead to early failure. Although it is important in small stress-small strain testing, specimen preparation is even more crucial to obtaining good results in failure testing. These challenges mean that failure tests can be expected to have higher variability – within your own lab and when comparing your lab’s data to another lab. That increased variability is not ideal for a purchase specification.

Failure to launch

As it was initially rolled out in 1993, the PG Asphalt Binder Specification – then designated as AASHTO MP1 – included a failure test. The Direct Tension test was intended to be conducted at low temperatures on asphalt binder that had been subjected to long-term conditioning to simulate many years of service on the road. It was a failure test intended to aid in the evaluation of the asphalt binder’s ability to resist thermal cracking at the specification temperature.

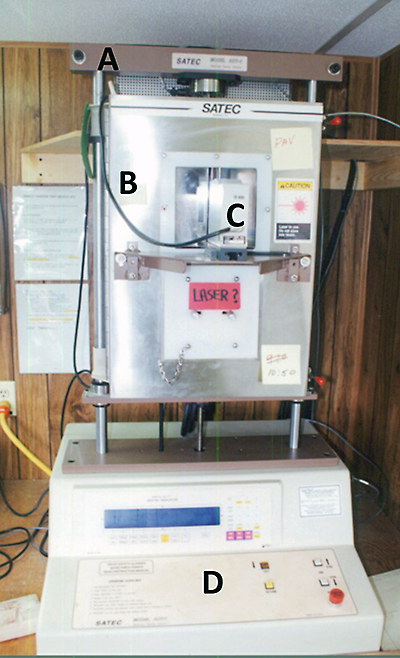

Figure 1 shows an image of the Direct Tension test equipment in a laboratory on a trial project. It consisted of a vertical load test frame (A) with an environmental chamber (B) capable of cooling to the low temperatures needed to characterize thermal cracking response. It used a computer control and data acquisition system (D) to record the stress and strain of the specimen at failure using a laser (C) that served as a non-contact extensometer.

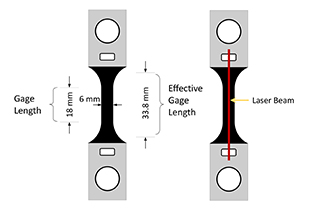

The Direct Tension test specimen is shown in Figure 2.

In Figure 2, the specimen sat on two ball joint pins such that the load would be transmitted through the center of the specimen, with the top pin moving at a prescribed rate and the bottom pin stationary. The laser extensometer created a beam that was blocked by the specimen except in the top and bottom holes in the specimen end pieces. As the test progressed, the computer recorded the distance that the two pinpoints of the laser beam moved apart and recorded that as the extension. Using that information, asphalt technologists could determine the strain at failure. The stress at failure was provided by the data from the load cell.

The argument for the use of the Direct Tension test was that it gave a way of characterizing the strain tolerance of asphalt binders for low-temperature thermal shrinkage cracking. On the one hand, according to the SHRP researchers “…for plain asphalt cements over a rather wide range of temperatures (stiffnesses), the strain to failure measured in a Direct Tension test is related in a general way to the stiffness of the asphalt.”

For polymer-modified asphalt binders, however:

“…it was observed that the addition of polymers can have a very significant effect on the low-temperature strain and energy to failure, often without affecting the rheological properties… Thus, the A-002A researchers concluded that strain tolerance as well as stiffness should be considered with respect to low-temperature thermal shrinkage cracking. This conclusion was reached on the basis of mixture data and field experience that shows that polymers and other modifiers can, in some cases, enhance resistance to low-temperature thermal shrinkage cracking. Including the strain at failure as a specification criteria [sic] ensures that the pavement will not transcend into the brittle region within its service temperature regime.”

As is common with failure tests, asphalt technologists found that the variability was high – much higher than other typical tests used in a purchase specification. Since the PG specification was a purchase specification – an agreement between the buyer (end users such as the state highway agency on paving projects) and the seller (asphalt binder supplier) – having confidence in the tests to produce accurate data was critical. Since failure strain was related to stiffness for unmodified asphalt binders and did not yield any new information that could not already have been obtained from testing using the Bending Beam Rheometer (BBR), the use of the Direct Tension test was left as an option, mainly for the benefit of polymer modified asphalts. In instances where the BBR stiffness did not meet the specification criterion at the low temperature, but the supplier felt that the asphalt binder would have sufficient strain tolerance that it could resist falling into the brittle region, the supplier/agency could conduct the Direct Tension test to validate that strain tolerance. In that manner the test, with its high variability and somewhat cumbersome specimen preparation and testing procedures, would not need to be used in routine testing for specification compliance.

Despite subsequent improvements to the test equipment, procedure, and analysis techniques the Direct Tension test never found its way into routine use for specification compliance. It still was a valuable tool, providing insight into the strain tolerance of asphalt binders, modified (traditional and non-traditional modification) and unmodified alike, but its utility as part of a performance-graded asphalt binder specification was never fully realized.

As easy as 1,2,3

The obvious rhyming of this section header with the following subject matter overrode my desire to stick with the spaceflight theme in which case “3,2,1” would have been more appropriate. I’ll leave it to you to decide which would have been better.

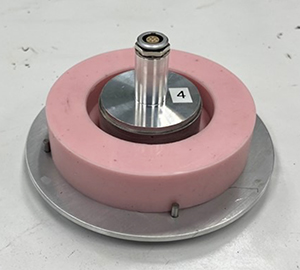

After the Direct Tension test effectively flamed out for use in a purchase specification, a second low-temperature failure test was developed. The Asphalt Binder Cracking Device (ABCD) was developed by Dr. Sang Soo Kim to get a direct measurement of the non-load-related cracking temperature of an asphalt binder. The ABCD test procedure, provided in AASHTO T 387, uses silicone molds into which asphalt binder is poured to create a ring of asphalt. In the interior of

the mold at the center is an Invar ring that includes a strain gauge to record the strain applied to the gauge by the contraction of the asphalt binder sample as it cools. There is also a surface-mounted resistance thermal detector (RTD) that records the temperature of the asphalt binder sample as it cools (Figure 3).

In the test procedure, the asphalt binder sample is cooled in an environmental chamber (Figure 4) at a prescribed cooling rate – a fast rate (40°C per hour) from ambient temperature until the sample reaches 0°C, then a slower rate (20°C per hour) from 0°C to failure. Using the current equipment and procedure, the coldest the test can be performed is -60°C.

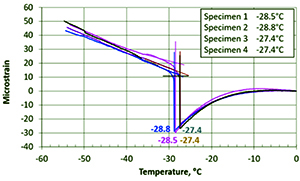

As the asphalt binder specimen cools, thermal contraction takes place causing strain to increase where the sample is in contact with the Invar ring/strain gauge. Eventually, the strain exceeds the strength of the asphalt binder and a crack occurs, immediately relieving the strain. The temperature is recorded at the time of this “strain jump” and is defined as the ABCD cracking temperature. This can be seen in Figure 5 showing the strain jump and ABCD cracking temperature for four specimens of the same asphalt binder.

According to the “Significance and Use” section of the AASHTO procedure, “The thermal cracking temperature can be estimated directly without elaborate assumptions and calculations by creating a condition similar to that encountered in the field.” This will certainly appeal to some asphalt technologists as it provides a direct measurement of thermal cracking.

Although the ABCD test is not part of the current PG Asphalt Binder Specification, it has been proposed for use by one national research effort, NCHRP 09-60, which is tasked to “…provide tools to measure the performance-related characteristics of asphalt binders and develop an updated specification that addresses current and future asphalt binders.”. As currently proposed by that research, the ABCD cracking temperature, Tcr, is normalized to a constant binder stiffness by using Tc,S – the continuous grade temperature at which the BBR Stiffness is exactly equal to the specification value of 300 MPa. The new parameter is termed ∆Tf (read as “delta Tf”) and is calculated by subtracting the ABCD cracking temperature (Tcr) from the continuous grade temperature for BBR Stiffness (Tc,S). If the ∆Tf parameter is positive, then the strain tolerance of the asphalt binder is better than would have been expected based on its stiffness. The more positive the value of ∆Tf the better the expected strain tolerance and an improved ability to resist low-temperature thermal shrinkage cracking. As expected, polymer-modified asphalt binders typically show more positive values of ∆Tf in the same manner as they did in the Direct Tension test years before in which they exhibited higher values of strain at failure than would have been expected based on their stiffness. In other words, a new way of analysis using an existing low-temperature failure test (ABCD) may provide insights into the strain tolerance of asphalt binders.

Mission debrief

The asphalt industry recognizes that asphalt binder formulation has changed significantly in the last 30 years, with new and different crudes being used in production, increased blending, and the use of new types of additives and modification. With cracking tests being increasingly used in characterizing mix performance asphalt binder formulators may want to consider how their products will perform in the linear viscoelastic region as well as the damage region where testing for failure may need to be an option. Although it adds to the complexity of testing, I think we can agree that it’s not rocket science.

Anderson is the Asphalt Institute Director of Research and Laboratory Services.