Twenty years ago, the Strategic Highway Research Program (SHRP) came to a conclusion providing the asphalt industry with the Performance-Graded (PG) Asphalt Binder Specification now described in AASHTO M320 and ASTM D6373.

Twenty years ago, the Strategic Highway Research Program (SHRP) came to a conclusion providing the asphalt industry with the Performance-Graded (PG) Asphalt Binder Specification now described in AASHTO M320 and ASTM D6373.

When I first would hear, and later give, presentations on the SHRP asphalt program I would always marvel at the idea of a 5-year, 50 million dollar research program. At first blush, five years seems like a pretty long time. Now, having participated in various research efforts over the past 22 years myself, five years seems like a really short time to develop new binder tests and the associated specification.

One of the improvements that we point to in describing how the PG specification represents an improvement over the older Penetration and Viscosity Graded specifications is that while the older specification systems accounted for short-term aging, in the form of Thin-Film Oven (TFO) or Rolling Thin Film Oven (RTFO) tests, there was no way of accounting for long-term aging effects. When SHRP researchers began reviewing aging of asphalt binders, they recognized that aging occurs during the mixing, laydown and compaction processes (short-term) as well as in-service on the roadway (long-term). The new PG specification needed to account for both short- and long-term aging.

So what to do? With a finite amount of time and money the researchers recognized that any efforts on asphalt binder aging needed to focus on long-term aging since it was not accounted for anywhere in the current specifications. The short-term aging protocols that already existed and were being used would have to serve.

The two short-term aging tests in use in the United States in the late 1980s and early 1990s were the TFO and RTFO tests. The TFO test was developed by the Bureau of Public Roads in 1940 and adopted by AASHTO (T179) in 1959 and ASTM (D1754) as a full standard in 1969. The RTFO test was proposed by the California Division of Highways in 1959 and adopted by ASTM (D2872) in 1970 and AASHTO (T240) in 1973. Both tests are intended to simulate the asphalt aging that occurs in a hot mix asphalt plant operating at approximately 150°C (approximately 300°F) thereby providing information about the aging tendency of the asphalt binder. Both tests also provide a measure of asphalt binder volatility.

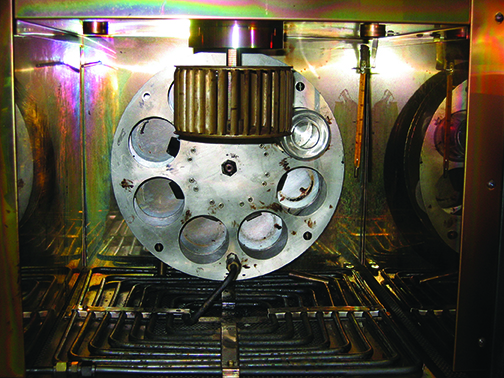

Despite the similar purposes, the tests differ significantly in operation. The TFO test is performed by first pouring 50 grams of asphalt binder into a 140-mm diameter stainless steel pan. The test sample is then placed on a rotating shelf in a natural draft oven operating at 163°C (325°F) for 300 minutes before removing the sample for further testing on the aged residue. The RTFO test is performed by first pouring 35 grams of asphalt binder into a 64-mm diameter glass bottle with a 32-mm diameter mouth opening. The test sample is then placed in a vertical rotating carriage (like a Ferris wheel) in a forced draft oven operating at 163°C (325°F) for 85 minutes while periodically blowing heated air into the bottles as the asphalt binder “rolls” – coating the interior of the bottle.

Ultimately the SHRP researchers selected the RTFO test as the short-term aging procedure to use in the PG asphalt binder specification because: Testing time was shorter than the TFO (85 vs. 300 minutes); precision of testing conducted on aged residue was better than the TFO; and skin formation cannot occur unlike in the TFO test.

In the time since SHRP ended and the PG asphalt binder specification started being used, the asphalt industry has seen a growth in the amount and type of modified asphalt binders used. Experience with the RTFO test indicates that some modified asphalt binders don’t roll within the rotating bottle, “…violating the basic premise of the test method (i.e., that the binder is exposed to heated air in a continuously moving thin film).”[3] Additionally, highly modified asphalt binders can creep out of the bottle during the test, creating a mess in the oven and negating the test.

The NCHRP 9-10 research project (described in NCHRP Report 459) concluded that the RTFO test did not adequately simulate the aging of modified asphalt binders. Modifications were proposed to the RTFO test to improve it, but did not meet with national acceptance. The general belief expressed by many asphalt technologists is that any short-term aging method should be applicable to all asphalt binders.

Finally, the NCHRP 9-36 research project (described in NCHRP Report 709) examined the short- and long-term aging of asphalt binders and provided some recommendations for the industry to consider. Although completed nearly two years ago, the chief recommendation – that the Modified German Rotating Flask (MGRF) is an acceptable alternative to the RTFO test for short-term aging of asphalt binders – is still being considered by industry. Although the MGRF test provides more aged material in a single test (200 grams), the time to conduct the test is longer (210 minutes) and the ability to measure volatility is not quite comparable to the RTFO test.

The RTFO test is easy to run, but not without faults. Any technician that has ever had the pleasure of cleaning asphalt binder off the coils in the bottom of a Rolling Thin Film Oven will tell you that when it comes to short-term aging of asphalt binders maybe it’s time we built a better mouse trap.

For more information on AI’s laboratory services please visit the AI website (www.asphaltinstitute.org) or contact Mike Anderson (manderson@asphaltinstitute.org).

Information in this article was derived from the following sources:

[1] Zupanick, M. “Comparison of the Thin Film Oven Test and Rolling Thin Film Oven Test”, Asphalt Paving Technology, Volume 63, Journal of the Association of Asphalt Paving Technologists, 1994.

[2] Petersen, J.C., R.E. Robertson, J.F. Branthaver, P.M. Harnsberger, J.J. Duvall, S.S. Kim, D.A. Anderson, D.W. Christiansen, H.U. Bahia. Binder Characterization and Evaluation: Volume 1, SHRP Report A-367, Strategic Highway Research Program, National Research Council, Washington, DC, 1994.

[3] Anderson, D.A. and R. Bonaquist. Investigation of Short-Term Laboratory Aging of Neat and Modified Asphalt Binders, NCHRP Report 709, National Cooperative Highway Research Program, Transportation Research Board, Washington, DC, 2012.

[4] Bahia, H.U., D.I. Hanson, M. Zeng, H. Zhai, M.A. Khatri, R.M. Anderson. Characterization of Modified Asphalt Binders in Superpave Mix Design, NCHRP Report 459, National Cooperative Highway Research Program, Transportation Research Board, Washington, DC, 2001.